Nylon Plastic Gears Industry Overview

Plastic gears have been used in various industries, including automotive, medical, agricultural, and office equipment. Among them, nylon plastic gears are one of the most common types of plastic gears used in different applications due to their excellent mechanical properties, such as high strength, stiffness, and wear resistance. In this article, we will provide an overview of the nylon plastic gears industry, their properties, types, applications, and future trends.

Nylon Plastic Gears Industry Overview and Informational Relationship with Nylon Plastic Gear

Nylon plastic gears are widely used in different industries due to their excellent mechanical properties. The nylon plastic gears industry is growing rapidly due to the increasing demand for lightweight, durable, and cost-effective gears. According to a recent report, the global plastic gears market is expected to grow at a CAGR of 4.5% from 2020 to 2025.

Nylon plastic gears are used in different applications such as robotics, aerospace, and medical equipment. The informational relationship between the nylon plastic gears industry and nylon plastic gear is that the industry manufactures and supplies nylon plastic gears to different companies producing various products such as medical devices, automotive parts, and household appliances that require nylon plastic gears.

Nylon Plastic Gear Properties

- High strength: Nylon plastic gears have high tensile strength, allowing them to withstand high loads without deformation.

- Stiffness: Nylon plastic gears have high stiffness, making them suitable for applications that require high precision and accuracy.

- Wear resistance: Nylon plastic gears have excellent wear resistance, allowing them to operate for longer periods without experiencing significant wear and tear.

- Low friction: Nylon plastic gears have low friction, reducing the wear and tear on mating parts.

- Chemical resistance: Nylon plastic gears have excellent chemical resistance, allowing them to resist the effects of acids, bases, and other corrosive substances.

Nylon Plastic Gear Types and Characteristics

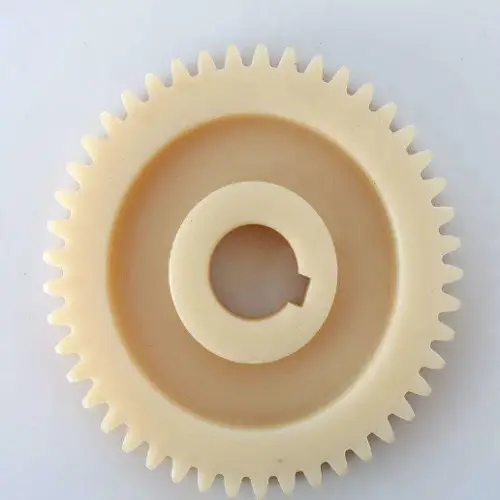

There are different types of nylon plastic gears, including spur gears, helical gears, bevel gears, and worm gears. Each type has its unique characteristics, making it suitable for specific applications.

- Spur gears: Spur gears are the most common type of nylon plastic gear. They have straight teeth and are used in applications where speed reduction or torque amplification is required.

- Helical gears: Helical gears have curved teeth that allow for smoother operation and reduced noise. They are suitable for high-speed applications.

- Bevel gears: Bevel gears have teeth that are cut at an angle, allowing them to transmit power between non-parallel shafts.

- Worm gears: Worm gears are used for high-torque and low-speed applications. They have a screw-like structure that allows them to transmit power at a right angle.

Nylon Plastic Gear Applications

Nylon plastic gears are used in various industries due to their excellent mechanical properties. Here are some of the applications of nylon plastic gears in different fields:

Home Appliances

- Washing machines: Nylon plastic gears are used in washing machines to drive the drum and control the speed of the motor.

- Vacuum cleaners: Nylon plastic gears are used in vacuum cleaners to drive the brush and control the suction power.

- Microwaves: Nylon plastic gears are used in microwave ovens to control the movement of the turntable.

Medical Equipment

- Surgical instruments: Nylon plastic gears are used in surgical instruments such as endoscopes and laparoscopes to control the movement of the instruments.

- Patient monitoring systems: Nylon plastic gears are used in patient monitoring systems to control the movement of the sensors that track vital signs.

- Implantable devices: Nylon plastic gears are used in implantable devices such as pacemakers to control the movement of the device.

Automotive Industry

- Power windows: Nylon plastic gears are used in power windows to control the movement of the window glass.

- Power seats: Nylon plastic gears are used in power seats to control the movement of the seat.

- Wiper systems: Nylon plastic gears are used in wiper systems to control the movement of the wiper blades.

Agricultural Equipment

- Tractors: Nylon plastic gears are used in tractors to control the movement of the wheels and other components.

- Fertilizer spreaders: Nylon plastic gears are used in fertilizer spreaders to control the movement of the auger that spreads the fertilizer.

- Harvesters: Nylon plastic gears are used in harvesters to control the movement of the cutting blades and other components.

Office Equipment

- Printers: Nylon plastic gears are used in printers to control the movement of the paper feed and other components.

- Copiers: Nylon plastic gears are used in copiers to control the movement of the paper feed and other components.

- Scanners: Nylon plastic gears are used in scanners to control the movement of the scanning head and other components.

Nylon Plastic Gear Future Trends and Opportunities

The nylon plastic gears industry is expected to grow in the coming years due to the increasing demand for lightweight, durable, and cost-effective gears. The development of new technologies such as 3D printing and advanced materials is expected to drive the growth of the nylon plastic gears industry.

One of the opportunities for the nylon plastic gears industry is the development of gears for electric vehicles. As the demand for electric vehicles grows, the demand for lightweight and durable gears is also expected to increase. Another opportunity is the development of gears for the aerospace industry, where lightweight and durable gears are required for critical applications.

How to Choose the Right Nylon Plastic Gear

Choosing the right nylon plastic gear is essential to ensure optimal performance and durability. Here are some factors to consider when selecting a nylon plastic gear:

Clarify Your Needs

Before choosing a nylon plastic gear, you need to clarify your needs, including the application requirements, load capacity, speed, and environmental conditions.

Material Selection

Choosing the right material is critical to ensure the optimal performance of the nylon plastic gear. In addition to nylon, other materials such as acetal, polycarbonate, and PEEK are also used in the manufacture of plastic gears.

Design Optimization

Design optimization is crucial to ensure the optimal performance of the nylon plastic gear. The gear design should be optimized to minimize stress concentration, reduce noise, and increase efficiency.

Supplier and After-Sales Service

Choosing the right supplier is critical to ensure the quality of the nylon plastic gear. The supplier should have a good reputation for quality and reliability and provide after-sales service and support.

Cost-Effectiveness

Cost-effectiveness is an important factor to consider when selecting a nylon plastic gear. You should choose a nylon plastic gear that offers a good balance between performance and cost.

Quality Control

Quality control is essential to ensure the optimal performance and durability of the nylon plastic gear. You should choose a supplier that has a robust quality control system to ensure the quality of the gear.

Nylon Plastic Gear Maintenance

Maintenance is essential to ensure the optimal performance and durability of the nylon plastic gear. Here are some maintenance tips:

Equipment Regular Inspection

You should inspect the equipment regularly to identify any signs of wear and tear or damage. This will help you identify potential problems before they become serious.

Cleaning and Corrosion Protection

You should clean the nylon plastic gear regularly to remove any dirt or debris that may accumulate on the gear. You should also protect the gear from corrosion by applying a suitable coating or protective material.

Lubrication and Maintenance

You should lubricate the nylon plastic gear regularly to ensure smooth operation and reduce wear and tear. You should also replace any worn or damaged parts and perform any necessary upgrades or improvements.

Why Choose Us

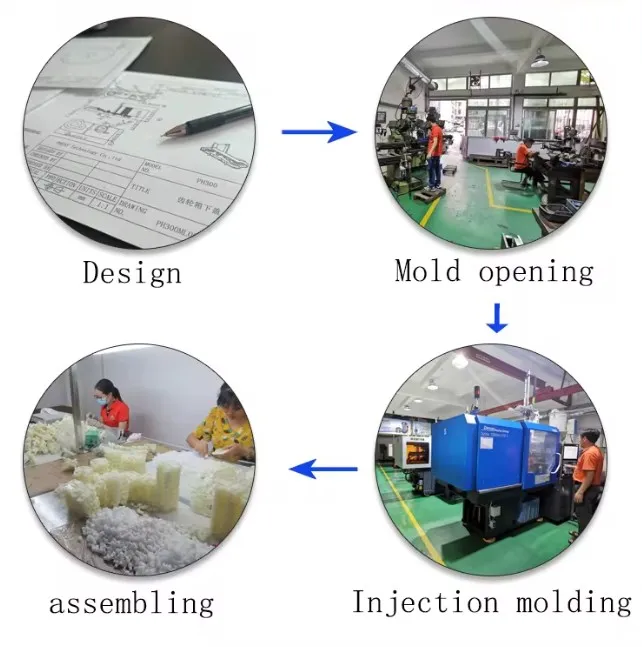

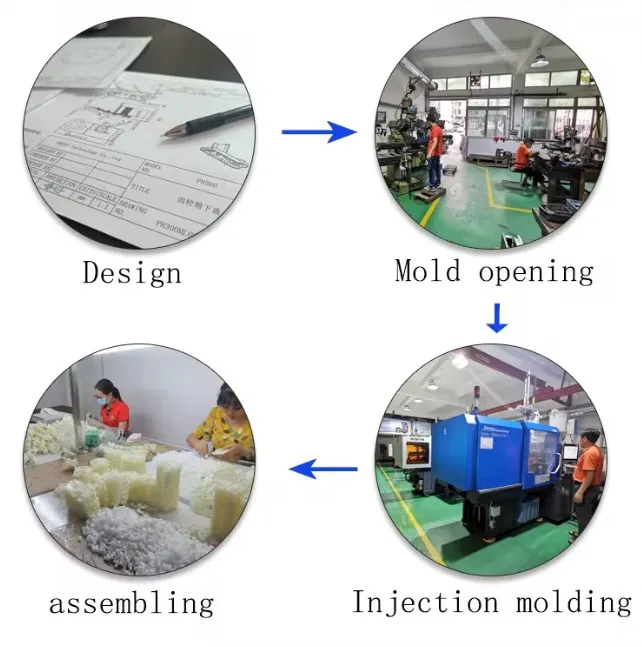

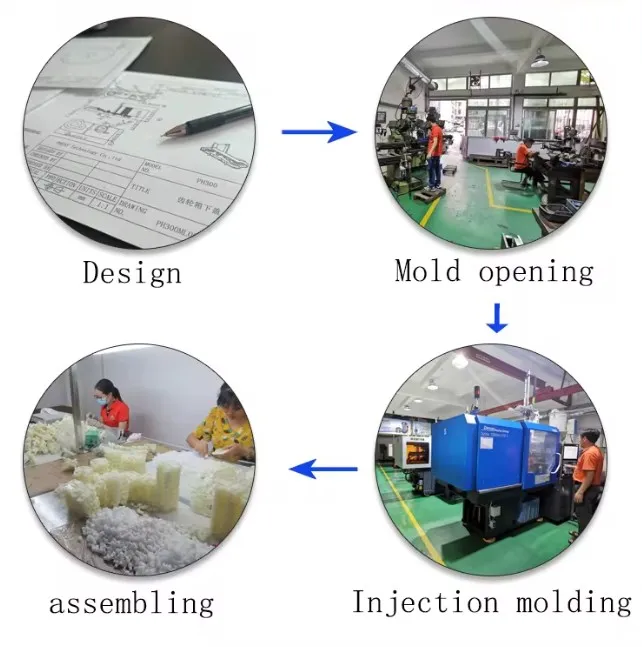

Our company specializes in the production and sale of nylon plastic gears. We offer a wide range of high-quality nylon plastic gears that are suitable for different applications and industries. Here are some of the reasons to choose us:

Quality Products

Our nylon plastic gears are of the highest quality, ensuring optimal performance and durability. We use advanced manufacturing processes and materials to produce gears that meet the most stringent quality standards.

Competitive Prices

We offer competitive prices for our nylon plastic gears, ensuring that our customers get the best value for their money. We offer bulk discounts and special promotions to help our customers save even more.

Customization

We offer customization services for our nylon plastic gears, allowing our customers to get gears that are tailored to their specific needs and requirements. We work closely with our customers to ensure that they get the gears they need.

Excellent Customer Service

We pride ourselves on providing excellent customer service, ensuring that our customers are satisfied with our products and services. We offer fast and reliable shipping, easy returns, and 24/7 customer support.

Expertise and Experience

Our team of experts has years of experience in the nylon plastic gears industry, giving us the expertise and knowledge to provide our customers with the best products and services. We stay up-to-date with the latest industry trends and technologies to ensure that we provide our customers with the best possible solutions.

Q&A

Q: What is the maximum temperature that nylon plastic gears can withstand?

A: Nylon plastic gears can withstand temperatures up to 150°C.

Q: Are nylon plastic gears suitable for high-speed applications?

A: Yes, nylon plastic gears are suitable for high-speed applications due to their high stiffness and low friction.

Q: What is the difference between spur gears and helical gears?

A: The main difference between spur gears and helical gears is that spur gears have straight teeth, while helical gears have curved teeth. Helical gears are quieter and operate more smoothly than spur gears.

Q: Can nylon plastic gears be used in wet environments?

A: Yes, nylon plastic gears have excellent chemical resistance and can be used in wet environments. However, they may require additional protection against water and moisture.

Q: Can nylon plastic gears be recycled?

A: Yes, nylon plastic gears can be recycled, making them an eco-friendly choice for different applications.

Author: Dream